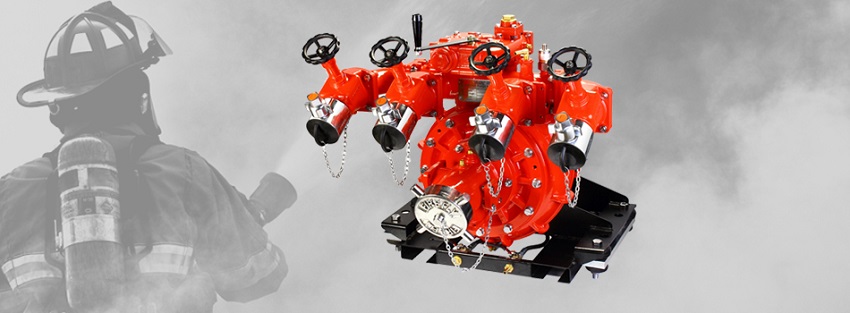

A Little Bit of Fire Pumps: Be in the Know Before Emergencies

Whether we're aware of it or not, sometimes we take nature for granted (I hate to say even most times) and we forget how to truly appreciate it. While it's beautiful and our source of life though we fail to see this often, it can be unforgiving same way if we don't pay enough attention to it. In Australia, we know what it can be like, we've seen its destructive face when heat waves strike. Considering the number of bushfires per week increased by 40% over the span from 2008 to 2013, we've sort of become accustomed to flames which is why fire fighting systems are our best friends, and it's not just in the Australian Outback but all around the overly populated areas too, regardless of whether it's for commercial or home use, buildings or houses. We can't always blame drought for being the main culprit, sometimes accidents can happen so every household simply must have its own fire pump because precious time can be lost while waiting for help to arrive. If you have a pool or pond, you could use them in emergencies as water supplies. There is certainly no shortage on pumps on the market either; Nowadays, thanks to technology you could buy fire pump online and this makes for easier purchasing.

11 April, 2017