Beneath the Heat: The Inner Workings of Plastic Bag Heat Sealers

As a community, we’re no strangers to the many benefits of using plastic bags. They are convenient, versatile and lightweight, with a wide range of applications in our daily lives. However, one aspect that is often overlooked is the process involved in sealing these bags to ensure their contents stay secure and intact.

After all, it is the heat-sealing process that keeps our food fresh, our medications safe and our industrial products protected. Way back when, people had to resort to using staples, tapes or adhesives to secure their bags. But thanks to advancements in technology, we now have a reliable and easy-to-use heat-sealing machine to get the job done safely and efficiently.

Contents

How Do Plastic Bag Heat Sealers Work?

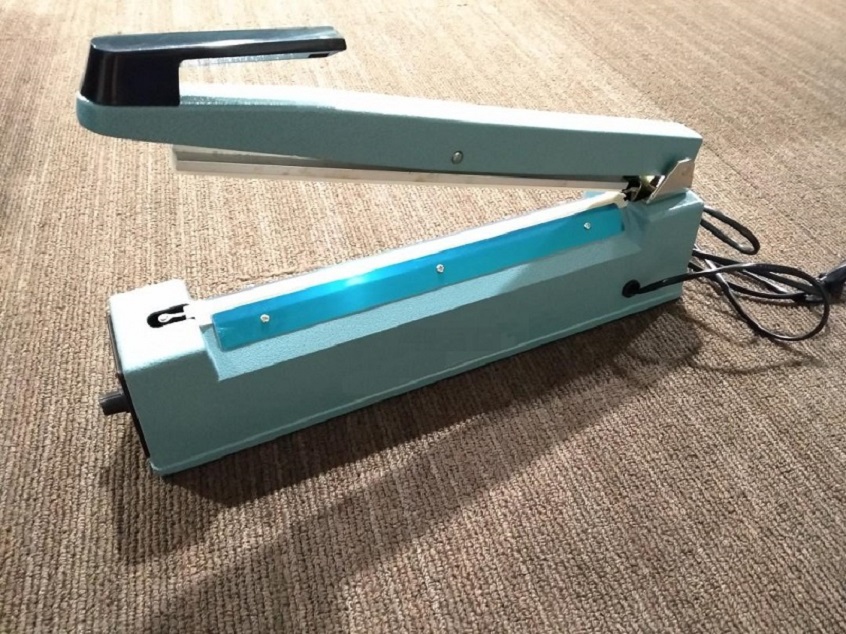

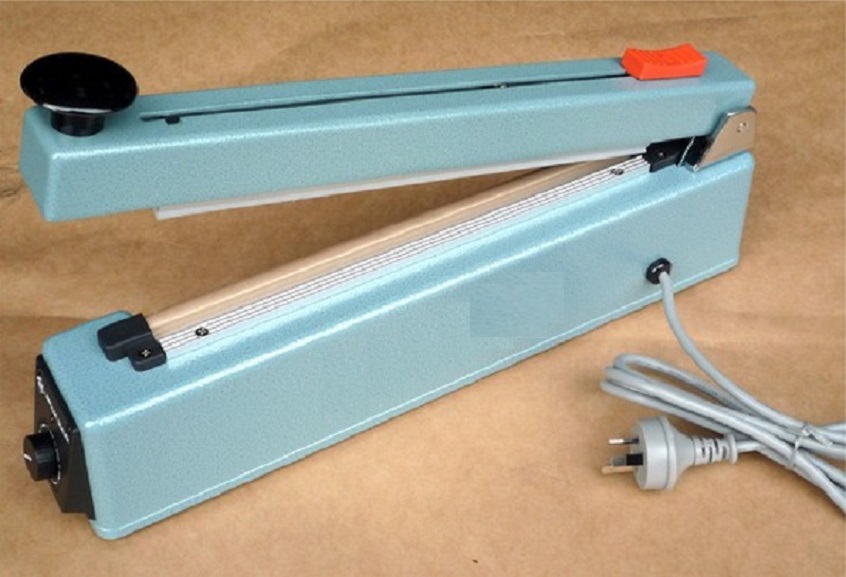

In a nutshell, these tools use controlled heat and pressure to fuse the two sides of a plastic bag together, creating a strong and reliable seal. The heat is applied through heated metal plates or wires, while the pressure is exerted by the machine’s jaws as it clamps down on the bag. When there’s enough heat and pressure, the plastic melts and cools down to form a seal. It’s a simple yet effective process that ensures the contents of the bag stay fresh and protected.

The temperature and duration of heat application can be adjusted depending on the type and thickness of the bag. The more heat and pressure applied, the stronger the seal will be. Given its precision and efficiency, plastic bag heat sealers are widely used in various industries and settings.

Applications of Bag Heat Sealers

These small yet highly functional machines have a wide range of applications, thanks to their versatility and reliability. Depending on the type of bag and its contents, you could use this tool in a variety of settings, including:

Food Packaging

Perhaps the most obvious use of heat sealers is in the food packaging industry. From sealing bags of chips to preserving frozen meals, these machines are essential in keeping food fresh and safe for consumption.

When they’re properly closed, plastic bags can prevent moisture, air and contaminants from entering the bag. This makes them ideal for storing and transporting food items that require a certain level of hygiene and freshness. If there’s any doubt as to the quality of a bag seal, it’s best to use alternative methods such as canning or vacuum sealing to ensure the contents remain safe for consumption.

Medical Supplies Handling

In the medical field, sterility and safety are of utmost importance. When there’s an open wound or a compromised immune system, the last thing anyone needs is contaminated supplies. Keeping the contents of medical bags secure is crucial, which is why heat sealers are commonly used to close and sterilise these packs before use.

When used in conjunction with proper storage and handling protocols, these tools provide an extra layer of protection against contamination and infection. If there’s any damage to the seal, it’s best to discard the bag and use a new one to avoid any potential risks.

Industrial Settings

In industrial settings, plastic bags are often used for packaging or transporting various products and materials. These could range from small components and hardware to heavy-duty equipment, depending on the specific industry. Regardless of the contents, using a heat-sealing machine to secure these packs ensures their safe and efficient transport.

Of course, you may require larger or more specialised heat sealers for heavy-duty bags and materials. But the principle remains the same – using heat and pressure to create a strong seal that can withstand various handling conditions.

At-Home Use

With more people looking for ways to reduce waste and save money, at-home use of plastic bag heat sealers has become increasingly sought after. These machines are handy for sealing leftover food, bulk pantry items and even preserving homemade goods like jams and sauces.

By having a reliable tool to close and protect these items, you can significantly reduce food waste and extend the shelf life of your pantry staples. However, it’s essential to follow safe handling and operation guidelines to avoid any potential accidents.

Key Factors to Consider

If you’re in the market for a heat sealer, there are a few key factors to keep in mind to ensure you get the right one for your needs. Some have better sealing capabilities, while others are more portable or easier to clean and maintain.

Size and Type of Bags to Be Sealed

Before purchasing a heat sealer, it’s crucial to know the size and type of bags you’ll be sealing regularly. This will determine the size and specifications of the machine you need.

For example, if you only close small food bags, a handheld machine may suffice. But if you need to seal large industrial bags regularly, you’ll require a larger and more powerful device that can handle the size and thickness of these packs.

Frequency and Volume of Sealing

Another factor to consider is how frequently and in what volume you’ll be using the heat sealer. If it’s for personal use, a smaller machine may suffice. But for commercial or industrial use, you’ll need a more durable and efficient model that can handle high volumes with ease. Naturally, the higher the frequency and volume of sealing, the more robust and reliable your machine needs to be.

Safe Handling and Operation

As with any machinery or equipment, it’s essential to follow safe handling and operation guidelines when using a heat sealer. This includes using appropriate protective gear, ensuring the device is in good working condition, and understanding how to use it correctly.

Keep an eye out for any potential malfunctions or damage to the machine, and always handle it with care. If you’re unsure about any of its functions or features, don’t hesitate to seek assistance from the manufacturer or a professional. You should also inspect and clean the machine regularly to ensure it’s in good working condition.