Everything You Need to Know about Oil Pumps

If your oil warning light comes up in the dash, you know you’re in trouble. This means that there’s low oil pressure, or simply not enough oil. The risks if you keep on driving are that all those spinning metal parts will soon heat up, and the resulting friction of the missing layer of oil that keeps them apart, will eventually seize the engine. This is catastrophic engine failure, and you’ll have to shell out thousands for a replacement engine (and other damaged parts) or get rid of the car.

Regular maintenance and oil changes are one way to ensure that this doesn’t happen. Another is to check all the parts responsible for getting oil to where it’s needed. This usually consists of the oil sump or pan, often located under the crankshaft, oil pumps to get things moving, filters to clean out any impurities, coolers or heat exchangers to cool the oil, and oil galleries weaving their way through the engine block. Other parts include pressure valves to restrict excess or allow for oil flow and sensors that gauge lubrication levels.

There are dozens of parts that require a decent dose of oil to work properly. This includes the main crank bearings; the big end bearings in conrods; the piston pins, small end bushes, and the piston rings; the camshaft and bearings lining; cam lobes, and the inlet and exhaust valves just to name a few. If any of these parts were to succumb to low oil levels, well then…meet your mechanic or new car dealer. You get the picture. Central in delivering oil to these and other parts (bearings lining water and fuel injection pumps, and turbines) is the oil pump.

Contents

The Necessities of Lubrication

A well-lubricated engine endures minimal or no power loss due to the increased friction between different moving parts. The film of oil provides a cushioning effect against engine vibrations, and there’s less wear and tear in parts as a result. Oil also helps keep the engine cool, and works hand in hand with the cooling system. Another vital function is to remove impurities in the oil and the internals, so there’s no risk of corrosion. Lastly, piston oil rings help with cylinder lubrication as well as sealing the cylinder to provide the right compression ratios.

Oil Pumps

The oil pump is at the heart of engine lubrication. This is a type of positive displacement pump, displacing a fixed amount of lubricant in a sealed system. An oil pump operates around a set of one or more gears driven by a shaft. As engine (and hence crank) speeds increase so does the flow of oil into the system. The pump circulates oil throughout the engine and feeds itself off the oil sump. Pumps push oil into filters and pressure then moves it through the oil galleries and channels in the cylinders.

Types of Oil Pumps

There are three major types of oil pumps used in cars – twin gear pumps, rotor pumps, and front cover oil pumps.

Twin Gear Pumps

Twin gear, or external pumps, consist of two meshing gears rotating in opposite directions of each other. One oil pump gear is driven by a shaft (either from the crank, camshaft or driving shaft), and the resulting movement turns the other gear. The tight tolerances between the two gears trap oil between the gear teeth (themselves with drilled inserts for required lubrication) and push oil toward the pump outlet. These pumps are usually located within the oil sump.

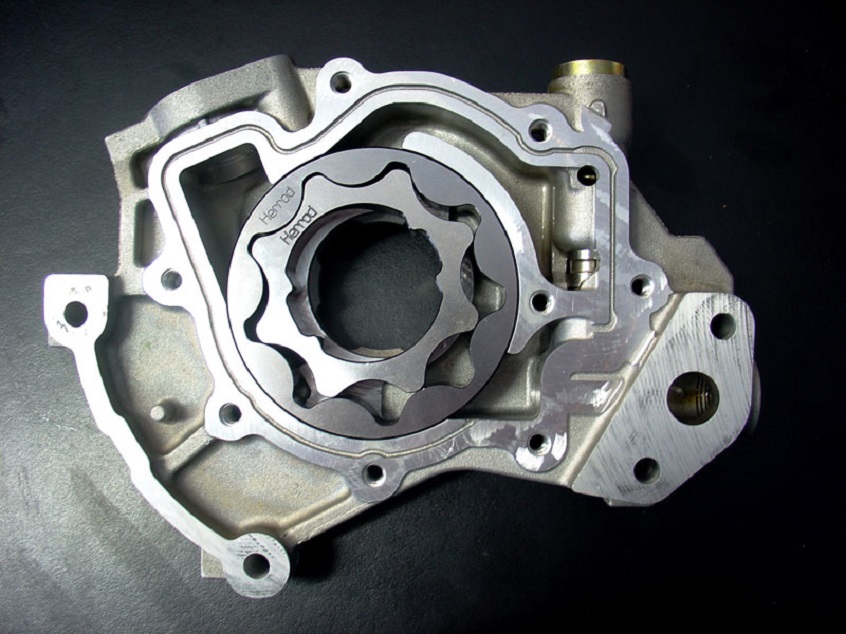

Rotor Pumps

Rotor (or ‘gerotor’) pumps get their name from the rotor around which an inner gear turns. The inner gear has one lobe less than that in the rotor and is mounted slightly off-centre. The outer rotor and inner oil pump gear spin at different speeds, effectively pulling the oil into the pump from the inlet valve and expelling it through the outlet valve. Rotor pumps can often be found in the crankcase.

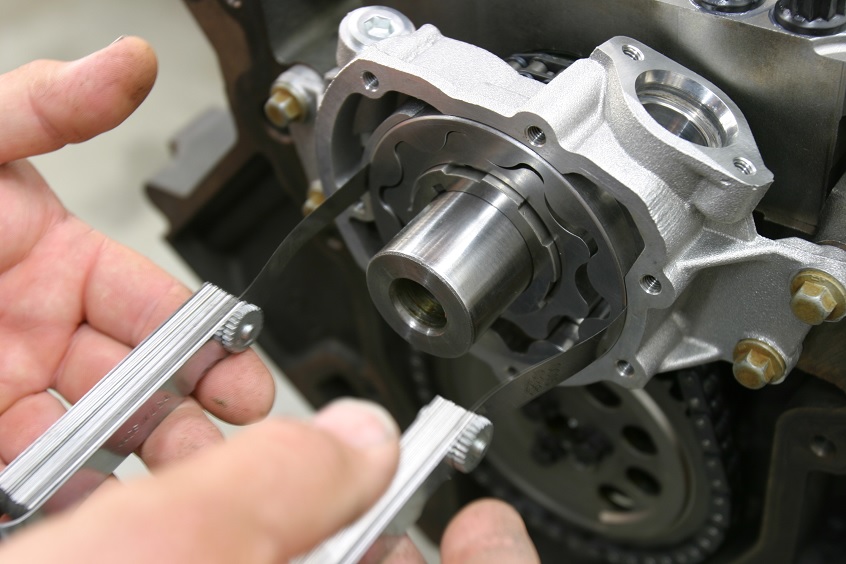

Front Cover Pumps

Also known as internal/external pumps, these are usually located in the front engine cover. They are a more advanced type of rotor pump, consisting of an inner drive gear and outer rotor, with the difference being the inner gear mounted directly on the crankshaft. This means the pump turns at the same speed as the engine (as opposed to twin gear pumps at half the operating speed), so oil pressure at idle is greater than either ordinary rotor or twin gear pumps. You’ll see these oil pumps in most SOHC and DOHC engines, as well as some later model push-rod engines.

Front cover pumps mostly have lower maintenance issues and worn gears or rotors can be replaced instead of the entire pump as is the case with the other two types. A drawback is that oil needs to travel longer distances to the pump, leading to the need for oil with lower viscosity.

Diagnosing Oil Pump Issues

Though most oil pumps will outlast other engine parts, problems do occur. Possible signs that the oil pump is defective or worn include the low oil pressure warning light, indicating that not enough oil is being pumped throughout the engine. This can also be from low oil levels due to leaks within the system, and not entirely down to the pump.

Another is higher than normal engine temperatures, with oil temperatures running slightly warmer than coolant temperature in a faultless engine. When oil temps get too high, oil starts to degrade and lose viscosity and the engine faces higher friction. What follows is thermal engine breakdown and not a pretty sight.

Lastly, noise from the camshaft and valves is another giveaway that oil isn’t circulating as it should, and another issue pointing to the oil pump.

Most newer cars have sensors that detect lower oil pressure, often tied to the ignition switch, and won’t allow the car to start if it detects lower than normal pressure or issues with the oil pump.

Either way, repairs can be costly if left too late.