Heat Management: Increase Performance and Engine Longevity with Heat Shields

Anyone who’s tuned an engine for more power knows what more heat can do to surrounding parts. And the more modifications you make to the stock engine with each tuning stage, the higher those temperatures will be. First to bear the brunt are essential engine components like the ECU and wiring, the fuel and brake lines, and airboxes and filters. When these get hot you’ll immediately notice lower engine performance.

Parts that are damaged or fail because of radiant heat pose a huge safety issue. That’s why proper vehicle heat management with the right heat-shielding products not only ensures optimal engine performance but also prevents potential hazards. The same products, encompassing heat shield sheet, tape and wrap are also used by car builders in restorations, as well as anyone looking to lower cabin temperatures.

Contents

The Range of Heat Shield Products

There are two things to consider when using heat shields. The first is that parts like turbos, exhaust manifolds, and engine blocks produce huge amounts of heat (some reaching 2000 degrees). Here thicker heat shield sheets, set at a 1 cm gap surrounding the component, work best at absorbing the radiant heat while maintaining optimal working temperatures. When containing heat in exhaust components, exhaust wrap applied in overlapping layers prevents the underbody, firewalls, and body panels from bearing the brunt.

The second is that a thinner adhesive heat shield can be directly applied to surrounding vehicle parts like wiring, hoses, fluid tanks and electronics that normally operate at much lower temperatures. This is to prevent the convective and conductive heat of hot engine parts from affecting how they work. The end goal is better performance throughout, especially in vehicles that have been modified or upgraded with faster spooling turbos, revised camshafts, forged internals, and performance exhausts among other options.

Heat Shield Sheeting

To maintain heat at the source, use thicker aluminium sheets. A 3mm heat shield sheet is effective in containing heat from engine compartments, the exhaust, transmission and undercarriage. Here you’ll find various systems and components that can reach 600 degrees or more. Aluminium is a good choice for controlling and managing radiant heat, as it has high thermal conductivity and low emissivity rates and comes with low weight and price. Moreover, it is easy to work with and can be shaped to suit the engine component. There are better results when going with copper heat shields, able to resist 800 degrees, but the material is heavier, harder to shape, and more expensive.

Sheets are relatively easy to form. They come in varying sizes, with 300mm by 500m and 500mm and 700mm more common, and are cut with tin snips or heavy-duty scissors. The cut sheets are then shaped with basic tools and placed at a 10mm distance from the engine component. This allows airflow to collect heat from the hot component but also prevents heat from spreading to surrounding parts. For the best results, look for kits with supplied mounting hardware, such as fasteners for areas like turbos and manifolds, or exhaust pipe mounts when fitting the sheet to exhaust components.

Adhesive Heat Shield

Aluminium foils with adhesive backing are good for managing heat in areas that don’t get as hot as those requiring a heat shield sheet. The foil is especially useful in tight spots, is easy to install, and is effective at temperatures of up to 250 degrees. Foils have a fibreglass core, an aluminium outer and a pressure-sensitive adhesive lining. The material is easy to mould to the contours of the vehicle part and can replace sheets in areas like firewalls, floor pans and the transmission.

Manufacturers offer at least two variants. Thinner foils at 0.05mm are a versatile solution to the uneven shapes and surfaces in parts like the airboxes, batteries, inner guards and the bonnet lining, whereas thicker (0.25mm) foils are more puncture resistant and are often used in exterior applications like exhausts and steering components. Installation takes a few minutes. The foil easily peels off the protective liner, moulds itself to the part and the sticky adhesive ensures it stays on. Another thing going for this heat-insulating product is that it also minimises vibrations and noise.

The foil may be familiar to racing enthusiasts as it’s been used for years in cars in official competition racing but has recently become available to the wider driving community.

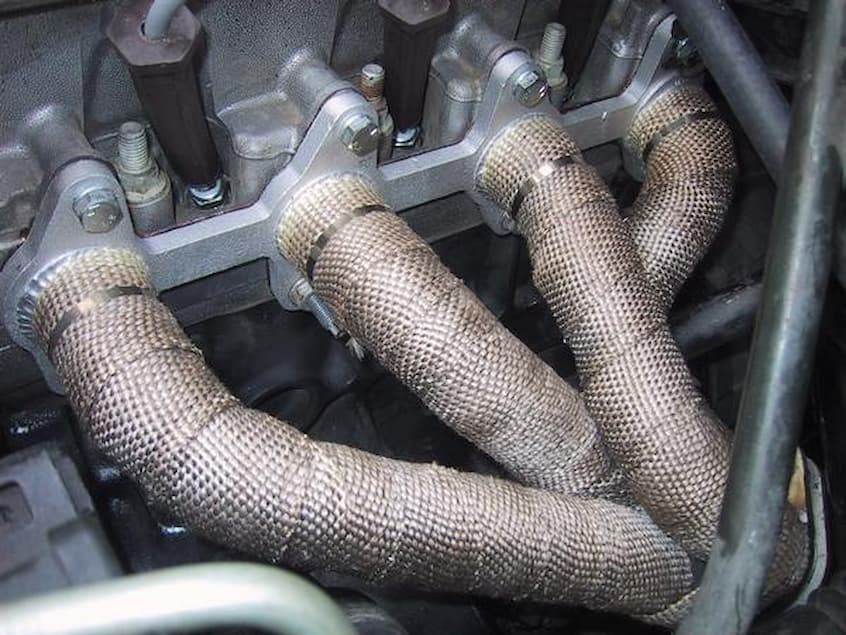

Exhaust Wrap

This is another heat-shielding product derived from racing. The wrap does a few things at the same time – it minimises heat from the exhaust creating uncomfortable cabin temperatures, shields the floor pan and body panels, and improves exhaust performance by increasing exhaust gas velocity.

There are a few types of wrap, each differing in materials. The ones with the highest temperature rating, up to 1200 degrees of continuous heat are titanium wraps. These not only keep more heat inside the piping but also add some style. They’re commonly used on air-cooled bikes, but also on car exhaust and turbo manifolds, downpipes, catalytic converters and other parts.

Like the other two products mentioned above, wraps are also quick and easy to install. Piping or parts are wrapped in overlapping layers down the whole length and kept in place with cable ties. Wraps are sold in 25-metre rolls, and in widths of 50mm (ideal for headers and collectors) or 25mm and used on the main piping.