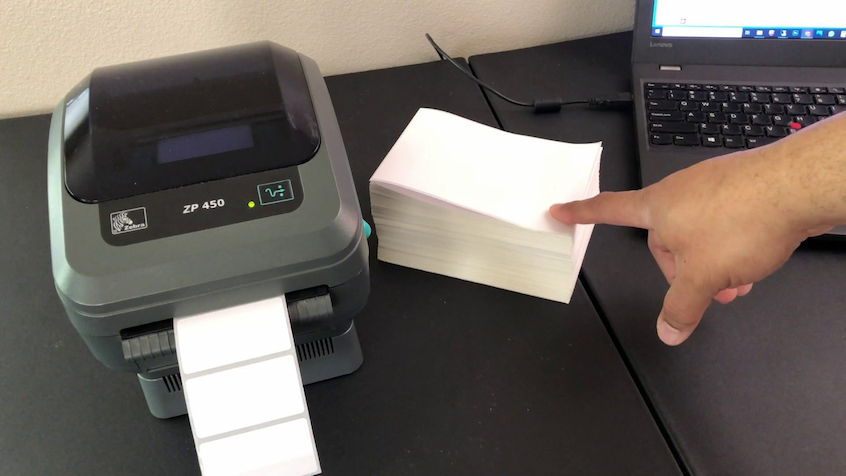

Your Guide to Choosing Label Printers

Whether you work in a warehouse, a factory, or an office, you’ve probably used a label printer at some point. They are not only extremely handy for labelling and organizing products, but they can also be quite useful for managing internal documents and data to guarantee that none of them goes missing.

A label printer is computer-controlled equipment that prints on self-adhesive label sheets. They’re usually designed to be connected to a computer that has the necessary software to create the label print. You can find this printer in the industrial and service sectors. A label maker, on the other hand, comes with a keyboard and software and may be used as a separate device to print labels.

Contents

All About Labels

Labels are significant because they distinguish a product, promote the brand, and provide information. Good labels for printer are designed to be suitable for an application, which means that the materials used in the label are appropriate for the environment. Label materials must withstand the demands of the application, have an adhesive that is optimal for sticking to the surface, and have a topcoat that will provide high-quality pictures, text and bar code.

Parts of a Label

The printer labels are made from different types of layers and each of them has its own function and purpose. They are specialized materials put together to make sure we get a label that looks good, lasts long and makes the product recognizable to the buyers.

Liner

The liner is a critical component of any pressure sensitive label. The liner is the backing paper that carries the die-cut labels to the applicator and releases the adhesive-backed label onto the product. The liner supports the label through manufacturing and use, protects the adhesive until the label is applied, and provides appropriate label application, either by automatic or mechanical means.

Liners come in different types to meet specific performance criteria. Typical performance and quality characteristics include strength, smoothness, density, release level, and stability. Liners can be made of paper or film.

Release Coating

The release liner goes on top of the liner. It has a very practical purpose that makes our lives much easier. It’s there to resist the adhesive and to ensure a smooth peeling from the liner. Because of it, the adhesive doesn’t get stuck to the liner.

Adhesives

You can use light or moderate pressure to get the labels to stick to the surface. How much pressure you need is determined by the label’s durability and the surface where it needs to stay. Think about the next things:

- How long will the label be on?

- What will the label leave behind if you remove it?

- What type of material will it be adhering to?

- Is the texture rough or smooth?

- What will the temperature be?

- What will the environment be?

- Will it be exposed to any solvents?

You’ll need to answer all of these questions before buying labels for printers. The ones made to be permanent will always leave some marks behind and won’t come out in whole, whereas the ones made to be removed after some time won’t give you such trouble. These adhesives can be made from rubber and acrylic. Rubber ones are quick to stick, water-resistant and very economical. Acrylic ones have a big temperature range, are easy to cut, resistant to UV and clear in colour.

Adhesives have different properties that are meant for different applications. Some of them are:

- Tack – the immediate holding strength;

- Ultimate Adhesion – full strength of bonding when taped to the surface;

- Resistance to Solvents – resistant to water, petrochemicals, alcohol etc.;

- UV Resistance – shouldn’t change colour and weaken;

- Adhere to Curvy Surfaces;

- Cold Flow – adhere to lower-than-normal temperatures;

- Application Temperature – don’t lose the grip when the temperature changes.

Facestock

The facestock is the main material that labels for printers are made of. It’s the top of the “face” of the label, hence, its name. Some of the most common materials are:

- Paper – most common and budget-friendly, best used indoors;

- Film – synthetic or plastic, for nursery applications and sewn-in tags mostly;

- Foil – layers of aluminium or alloys;

- Tag – stock of 5-10mm without adhesive or liner;

- Tape – film or paper with adhesive but no liner;

- Magnets – the top layer is paper or film and the bottom is magnets;

- Holograms – for identification and security, very durable.

- Matte – dull finish, for barcodes and QR codes.

Topcoat

This layer protects the facestock from absorbing moisture, from wear and tear and can enhance some parts of the label. It can also be UV sensitive depending on the conditions it will go to.

Thermal Labels

Thermal labels are ideal for printing content such as ingredients, dates and barcodes on the spot. The two best options for this that you should take into consideration are direct thermal and thermal transfer.

Direct Thermal

This process involves applying chemical layers to the paper or the synthetic base that gets activated by heat. When this printer prints the label, it heats the small elements on the paper and this activates some parts of the chemical layer which is how the images are created. This type of paper labels for printers is used in shipping, weigh scale, warehouse, receipts, tickets etc. All of these have a short to medium life application. It’s simple to use, goes with most printers and it’s very cost-effective. The only disadvantage is that it will fade in 6-12 months making it hard to read.

Thermal Transfer

This type of printing requires a ribbon. During the printing process, this ribbon is heated and transfers the marks to the paper creating an image or a text. This way the final result will be long-lasting and suitable for outdoor labelling and places where the moisture levels are high such as a laboratory, warehouse, inventory labelling and industrial and chemical labels. Thermal transfer is perfect for lines and small characters and is suitable for both 1D and 2D barcodes. It’s also chemical and heat-resistant with a higher-printing speed. The downside is that the ribbons can sometimes wrinkle and cause some damage to the printer.

In Summary

The labelling industry is very big, and people and companies have different needs every day. That’s why, manufacturers developed so many types of labels to accommodate every need on the market. This industry is still on the rise and more and more new inventions are coming each day.